Plush products are beloved for their soft texture, cuddly appeal, and wide range of designs, from cartoon characters to custom stuffed animals. However, when sourcing or manufacturing plush items, it’s important to understand the distinction between plush doll manufacturers and plush toy manufacturers. While both produce soft, stuffed products, they differ in design focus, target market, production techniques, and quality standards. Below is a detailed comparison of the two.

1. Definition & Product Focus

Plush Doll Manufacturers

Specialize in creating anthropomorphic or character-based plush items, often resembling human-like dolls (e.g., baby dolls, anime characters, or branded mascots).

Emphasize facial features, hairstyles, and detailed accessories (e.g., dresses, bows, or costumes).

Common products include reborn-style dolls, collectible character plush, and fashion dolls.

plush toy Manufacturers

Focus on general-purpose stuffed animals or animal-shaped plush (e.g., teddy bears, unicorns, pandas, or custom animal designs).

Prioritize softness, huggability, and durability rather than intricate human-like details.

Products are often marketed as children’s toys, comfort objects, or promotional giveaways.

2. Target Market & Use Cases

Primary Buyers: Collectors, children (especially for role-playing), and gift markets.

Use Cases:

Collectible dolls (e.g., Disney characters, anime plush).

Reborn dolls (hyper-realistic baby dolls for collectors).

Fashion dolls (with interchangeable clothing).

Primary Buyers: Parents, daycare centers, and promotional brands.

Use Cases:

Children’s toys (teddy bears, educational animal plush).

Comfort items (for anxiety relief or sleep aids).

Corporate gifts & branding (custom logo plush animals).

3. Design & Manufacturing Differences

Plush Doll Manufacturer

Detailed Stitching: Requires precise facial embroidery, jointed limbs, and movable parts (e.g., arms that bend).

Hair & Accessories: May involve rooted hair (like dolls) or sewn-on wigs, plus additional accessories (hats, shoes).

Higher Craftsmanship: Often involves hand-sewn details for realism.

Plush Toy Manufacturer

Simplified Design: Focuses on basic shapes (round bodies, stuffed limbs) with minimal stitching complexity.

Material Choice: Prioritizes ultra-soft fabrics (minky, fleece) for hugging comfort.

Mass Production Friendly: Easier to automate, making them cheaper to produce in bulk.

4. Quality & Safety Standards

Plush Dolls

Higher Safety Scrutiny: Especially for baby dolls (small parts must be non-choking hazards).

Material Premiumization: Often uses higher-grade stuffing (polyester fiberfill) and hypoallergenic fabrics.

Plush Toys

Durability Focus: Designed to withstand rough play (reinforced stitching, double-stitched seams).

5. Cost & Production Volume

Plush Dolls

Higher Production Cost: Due to complex detailing, smaller batch sizes, and premium materials.

Lower MOQ (Minimum Order Quantity): Some manufacturers accept smaller orders (500-1,000 pcs) for custom designs.

Plush Toys

Lower Cost per Unit: Simpler designs allow mass production at lower prices.

Higher MOQ: Often requires 5,000+ units for custom designs due to automation efficiency.

6. Customization & Branding

Plush Dolls

Ideal for Limited Editions & Collectibles (e.g., signed artist dolls, exclusive releases).

Customization Options: Different hairstyles, outfits, and facial expressions.

Plush Toys

Best for Branded Merchandise (e.g., company mascots, promotional gifts).

Customization Options: Logo printing, color variations, and basic shape adjustments.

The following are some examples of plush toys that our factory customizes for customers. Check out if there is one that you like best.

-

Custom Animal Plush

-

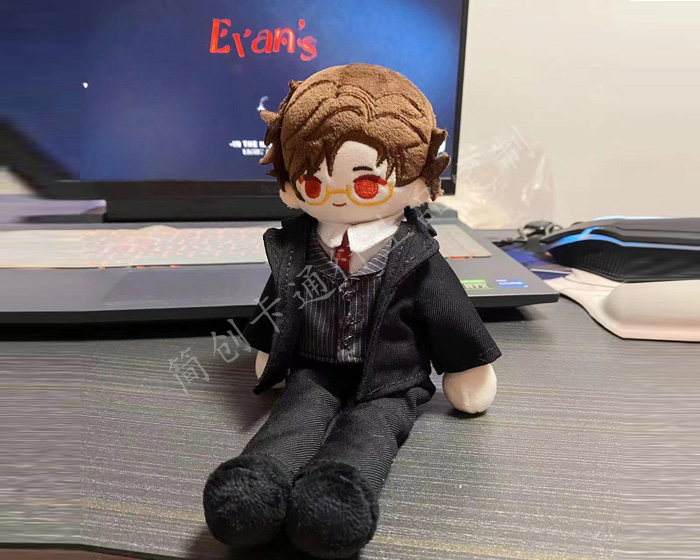

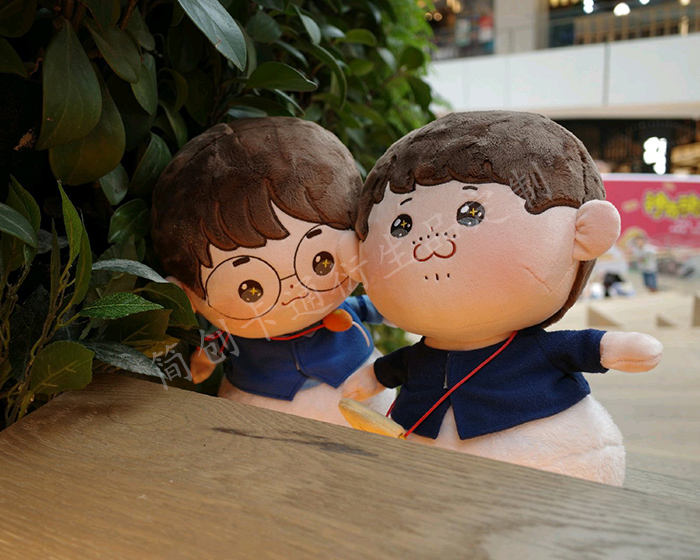

Cute Plush Doll

-

Custom Stuffed Animals

-

Plush Toy

-

Plush Dolls

-

Custom Stuffed Dolls

-

Custom Plush Toy

-

Cotton Dolls

-

Weighted Plush Toys

-

Cute Stuffed Animals

-

Custom Pet Stuffed Animal

-

Warmies Stuffed Animals

-

Weighted Stuffed Animal

-

Soft Toys

-

Plush Stuffed Doll

-

Custom Stuffed Dolls

-

Plush Maker

-

Bear Stuffed Toy

-

Anime Plush

-

Custom Stuffed Animal

-

Anime Plush

-

Custom Plush Toy

-

Personalised Stuffed Animal

-

Plush Animal Toys

-

Custom Plush Makers

-

Custom Plushies

-

Toy Manufacturer

-

Rag Doll Making

-

Custom Toys

-

Dog Plush Toys

-

Custom Rag Doll

-

Stuffed Animals

-

Custom Plush

-

Custom Plush Dolls

-

20cm Cotton Doll

-

Jojo Plush

-

Custom Doll

-

Jojo Doll

-

Large Plush Toys

-

15cm Cotton Doll

-

Dumpling Plush

-

Cotton Doll