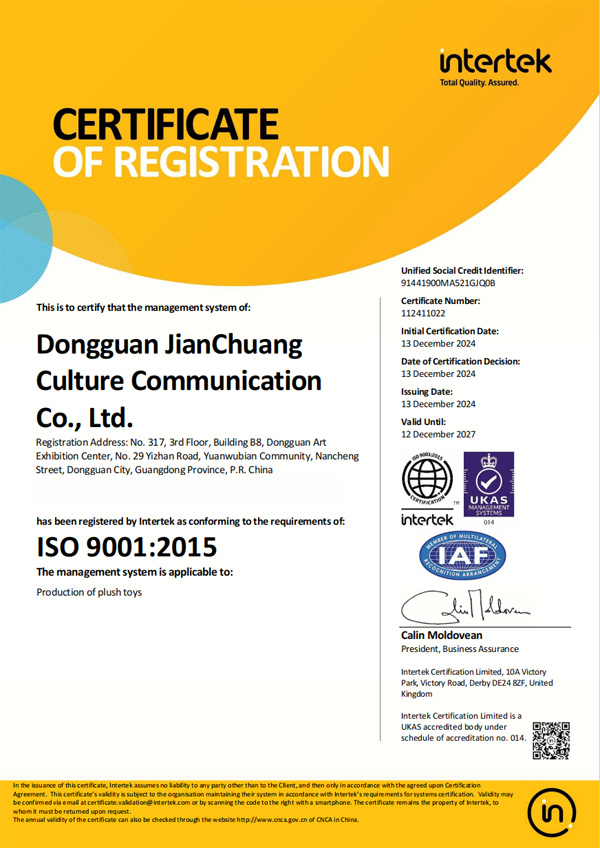

Dongguan Jianchuang Culture Communication Co., Ltd.(Abbreviation: Jianchuang) is located in Dongguan City, Guangdong Province, the global manufacturing center. It is a plush product customization factory certified by ISO9001:2015 international quality management system. Focusing on the customized production and processing of IP cultural creation, peripheral plush toys, trendy dolls and other derivative products.

Dongguan Jianchuang Culture Communication Co., Ltd.(Abbreviation: Jianchuang) is located in Dongguan City, Guangdong Province, the global manufacturing center. It is a plush product customization factory certified by ISO9001:2015 international quality management system. Focusing on the customized production and processing of IP cultural creation, peripheral plush toys, trendy dolls and other derivative products.

Since its establishment in 2018, we have maintained close cooperation with many painters, animation designers, well-known animation brands and government units, and established a long-term strategic partnership. We adhere to the concept of being down-to-earth, far-sighted, and actively innovative, and take customers as the center to continuously optimize the production process.

In terms of customized plush toys, we cover maternal and child toys, cotton dolls, doll clothes, doll bags, cloth bags, dumplings, card holders, scarves, hats, coin purses, blind box dolls, trendy dolls, fan peripheral dolls and company mascots. Our team is composed of experienced proofing masters, professional development and design personnel, and production management personnel. With more than ten years of industry experience, we can accurately grasp market trends.

We have established a complete pre-sales and after-sales service system to ensure that every plush product can exquisitely reflect the principle of "quality first, service first". Currently, our authorized cooperation brands include "Maltese puppy", "Cardcaptor Sakura", "One Two Bubu", "Siamese Cat", "DRDR Original Design", "Little Sheep Cat" and other IP brands.

While developing rapidly, we always pay attention to product quality and customer service, and sincerely welcome new and old customers to discuss cooperation!

Our factory has passed the ISO 9001:2015 international quality management system certification (certificate number: 112411022), and strictly controls the quality of each plush product according to international standards.

Over seven years of dedicated effort, we craft every inch of plush with the heart of a craftsman. From fabric selection to craftsmanship, we've focused on one thing: ensuring every custom plush piece embodies warmth and quality. Countless proofing and adjustments are made to recreate the perfect soft touch you desire.

With over a decade of experience as a skilled pattern maker, we've cultivated our skills through years of experience, focusing on accurately transforming every design into a physical sample. Familiar with the characteristics of various materials and the challenges of craftsmanship, we rigorously control dimensions, patterns, and details. We've produced thousands of samples, achieving an industry-leading success rate.

Since our founding, we have always adhered to originality and high quality standards, rejecting cookie-cutter copying. From design sketch to finished product delivery, we infuse every step with ingenuity – selecting premium plush fabrics, meticulously controlling craftsmanship details, and infusing each piece with a unique soul through exclusive creative design.

Normal body

The most common cotton doll is 10cm15cm20cm

Chubby body

A bit fatter than normal

Starfish body

Short limbs like a starfish

Ant Body

The limbs are slender and agile, like a slender ant

Ball body

A round thing with a head but no limbs

Hand puppet

Plush toys that you can put your hands into

Animal figures

Animal-shaped plush toys

Long-legged body

Long legs with elongated legs

The sewing department of a plush toy factory is a key step in product development. It's responsible for precisely stitching together various pre-cut plush fabrics (such as short plush, long plush, and polar fleece) using specialized sewing equipment, ultimately forming the toy's basic structure. This department is typically equipped with a variety of industrial sewing machines, including flatbed, high-rise, and synchronous sewing machines, along with hot melt adhesive machines for additional fastening depending on process requirements.

The sewing department's workflow typically begins with pre-processing the fabric and accessories (such as hemming and overlocking). Subsequently, the various components (such as the body, limbs, and ears) are assembled and sewn according to the design. Key priorities are ensuring uniform, fine stitches and consistent stitch lengths to prevent thread unraveling or cracking. For toys that require stuffing, precise filling openings must be reserved, and the edges must be overlocked to prevent the plush from protruding.

The filling department in a plush toy factory is crucial for determining the toy's feel and fullness. They're primarily responsible for evenly filling filling materials like PP cotton and down into the toy's cavities, created during sewing. This ensures the toy's soft, fluffy feel and three-dimensional shape.

Operators must precisely control the filling amount and uniformity based on the toy's design standards (such as weight, firmness, and shape). For example, stress-bearing areas like the head and limbs require firmer filling to maintain support, while the abdomen or back can be slightly looser for a more comfortable feel. Furthermore, they pat and adjust the filling opening to prevent hollow areas, cotton clumps, or uneven surfaces.

The handcrafting department of a plush toy factory is the core element that imbues toys with life and detailed texture. Responsible for performing delicate operations and personalized decorations that machines can't precisely achieve, it serves as a crucial bridge between standardized production and consumers' emotional needs.

The work encompasses several meticulous steps: First, hand-trimming and hemming the toys after initial sewing. For example, this involves trimming rough edges with scissors and reinforcing areas prone to unraveling with hidden needles to ensure smooth, burr-free edges. Second, filling assistance is required. For unusual shapes (such as the tips of cartoon characters' wings and tails), the appropriate amount of cotton is manually filled in and evenly distributed to avoid areas of stiffness or gaps caused by machine filling. Even more crucial is decorative assembly: hand-sewing facial features (eyes, nose, and mouth), applying whiskers or patterns, and attaching accessories such as bows and bells. For high-end custom toys, even personalized elements like embroidered names and hand-painted designs are added.